Isuzu өрт сөндіру көлігі - өртке, жол-көлік оқиғаларына және басқа да авариялық-құтқару миссиялары үшін көп мақсатты арнайы құрал Жоғары қысымды су сорғыларымен, үлкен сыйымды су ыдыстарымен немесе көбікпен өрт сөндіру құралдарымен және түрлі-құтқару құралдарымен жабдықталған, Ысқұтқыштар сахнаға тез жетуге, өртті тез арада сөндіруге және құтқару жұмыстарын жүргізуге мүмкіндік береді

Сондай-ақ, Изузу өрт сөндіру көлігі өрт сөндіру машинасы, өрт сөндіру машинасы, көбік өрт сөндіру көлігі, өрт сөндіру машинасы, өрт сөндіру машинасы (өрт сөндіру машиналары) - өрт сөндірудің алдын-алу үшін қарапайым, өрт сөндірудің алдын алу, өрттің пайда болуының алдын-алу, өрттің пайда болуын азайту, жоғалтуды азайту

Изузу өрт сөндіру көлігі еріп жатқан денеде, әдетте, қызыл түске ие, бұл төтенше жағдайдан тез анықтауға оңай Оның сипаттамалары - өрт сөндірудің күшті мүмкіндіктері және жан-жақты құтқару функциялары Бұл өртті тез бақылау үшін көп мөлшерде су немесе көбік шашырап, көбік шашырап, оларды сақтау үшін жабдықтарды, мысалы, қақпақтарды сақтауға арналған жабдықты пайдаланады

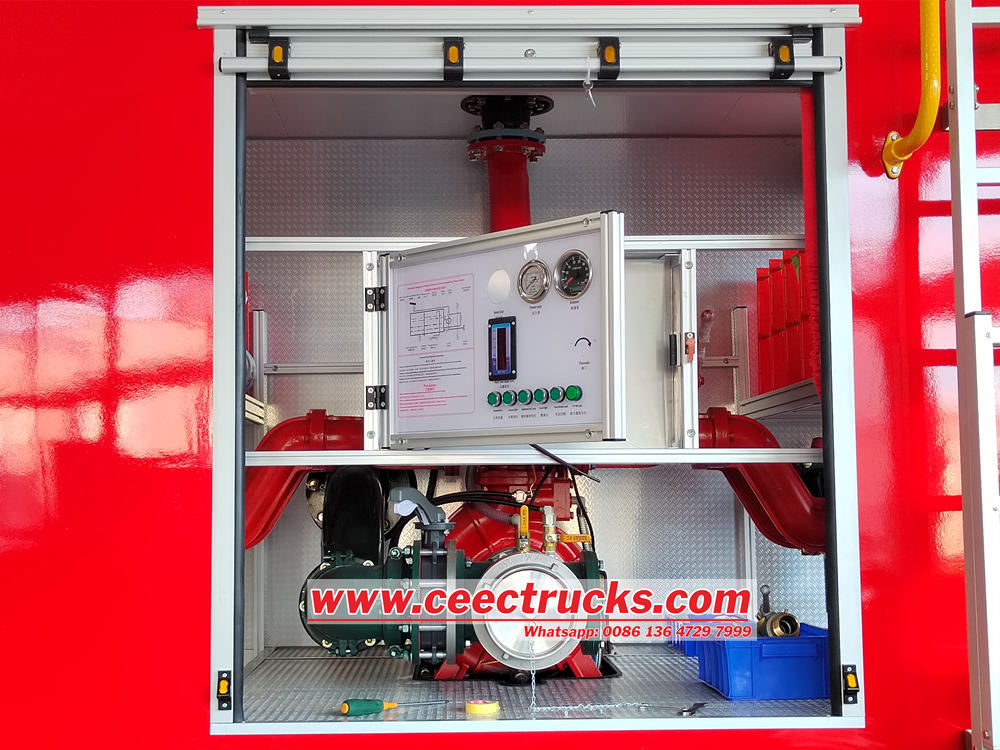

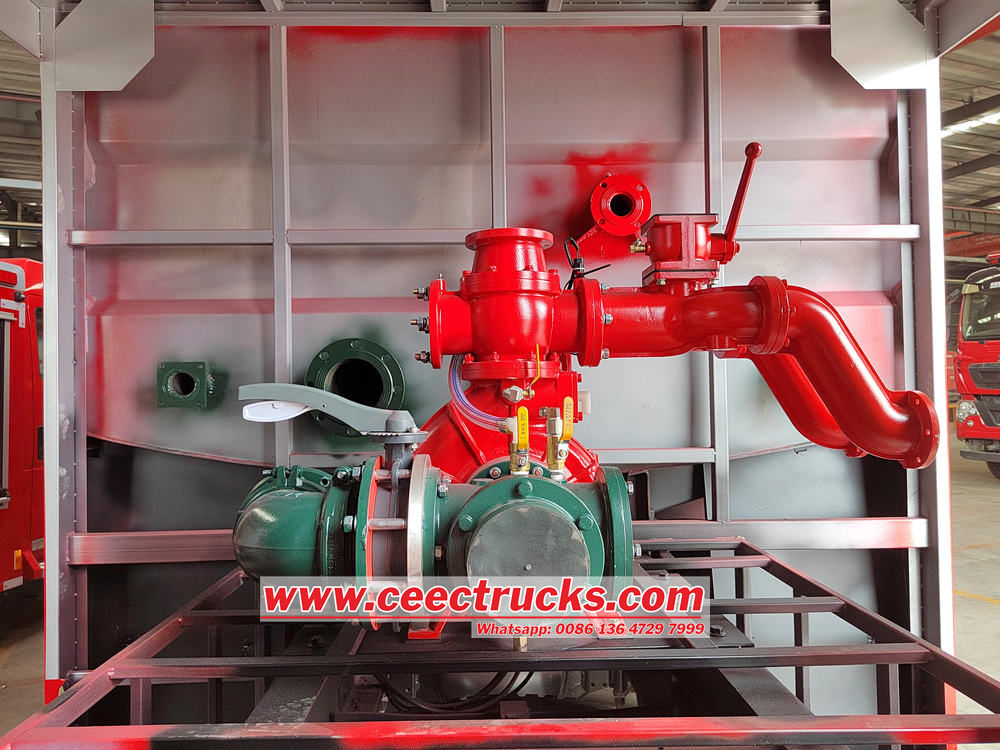

Isuzu өрт сөндіру көлігі Isuzu Giga 4x2 шассиінің негізінде өзгертілген Көлік құралы 6UZ1-380HP қозғалтқышымен, қуаты берік қуатпен және жылдам редукторды жылжытуға арналған жылдам 12 жылдамдықпен жабдықталған Көліктің жалпы сыртқы өлшемдері - 7900x2500x3500 мм, доңғалақты 4600 мм Көлік құралының алдыңғы жағы - бұл өрт сорғы бөлмесі, CB10 / 60 өрт сөндіру зеңбіректері орнатылған Көлік құралының ортасында 8000л көміртегі су ыдысы, ол ұзақ мерзімді өрт сөндіру немесе су бүрку жұмыстары үшін көп мөлшерде су әкелуі мүмкін

Үлгіuck шасси | ||

Улгі | Параметрлер | басқалары |

Шасси | Изузу Гига | Өртке қосымша |

Gvw | 25000кг | |

Қозғалтқыш моделі | 6Ғы зор1-TCG61 | Isuzu |

Қозғалтқыш қуаты | 380 гп | |

Доңғалақты | 4600мм | |

Жүргізу түрі | 4x2 / 6WHEELS | Сол қол |

Берілу | Жылдам 12-ауысым | Нұсқау |

Шығарындылар стандарты | 15681 мл | Еуро 6 |

Жолаушы жоқ | 3+3 | |

Кабина | 4 Есіктер, екі орындық орын | A / c |

Жалқауr танк | |

Сыйымдылық | 8 000л |

Материал | Көміртекті болат, Қалыңдығы мин = 4 мм |

Даймаққа арналу | Резервуар ауырлық центрі мүмкіндігінше төмен деп есептеледі |

Ссуспъiк | Барлық металл дәнекерлеу құрылымы, жалпы коррозияға қарсы тұрақтылық, соққылар сіңіру шаралары бар |

Жабдықталған | Сорғы бөлмесінің артындағы 1 сорғыш |

1 Толтырғыш клапан құрылғысы | |

1 доп клапанымен су төгетін розетка | |

1 ½ дюйм, 2 ½ дюйм және 4 дюймекі жағынан да,Құрылымы: Ішкі иісі бар доп клапанықұбыр жолы | |

Өрт сорғысы | ||

Улгі | CB10 / 60 |

|

Басу | БТапсырма сорғысы | |

Номиналды ағын | 60L / s @ 1 0MPA | |

Шығу қысымы | ●§1 3 МПа | |

МAX сорғы биіктігі | 7м | |

БҚуатты құрылғы | VАкуум сорғысы | |

Бжақтау уақыты | ● § 45s | |

-Перед | Дризор PTO сорғы / жүргізушілердің салонының ішінен, барлық басқа операциялар сорғының артынан, көлік құралының артқы жағынан жасалады; | |

Үздік Изузю өрт сөндіру көлігін өндіруде мұқият жоспарлау, сапалы материалдар, өндірістік процестер жатады Міне, Изузю өрт сөндіру көлігінің өндірісін қамтамасыз етудің үш негізгі қадамы:

1 Жетілдірілген дизайн және жоспарлау

Өндіріс басталғанға дейін, дизайн және жоспарлау кезеңі өте маңызды Бұған мыналар кіреді:

Жан-жақты дизайн: Инженерлер барлық қажетті қауіпсіздік пен өнімділік стандарттарына сәйкес келетін өрт сөндіру көлігін жобалау үшін бірлесіп жұмыс істейді Олар өрт сөндірудің қатаң талаптарын шеше алатындығына көз жеткізу үшін көлік құралының өлшемдері, салмағы және жалпы құрылымына назар аударады

Материалды таңдау: Жоғары сапалы материалдар беріктік пен сенімділік үшін таңдалады Мысалы, су ыдысына арналған коррозияға төзімді материалдар үшін берік металдарды пайдалану ұзақ мерзімді жұмысын қамтамасыз етеді

Ерекшеліктерді теңшеу: Клиенттер өрт сөндіру көлігін және салонның өлшемдерін, өрт сөндіру көлігін белгілі бір опцияларды, мысалы, өрт сөндіру көлігін белгілі бір қажеттіліктерге бейімдеуге мүмкіндік береді

2 Дәлдік өндіріс

Өндірістік кезеңдерде дәлдік - бұл маңызды:

Құрастыру сызығының тиімділігі: Өндіріс желісі әр компоненттің дұрыс және тиімді жиналуын қамтамасыз ету үшін оңтайландырылған Жетілдірілген робототехника және автоматика көбінесе дәлдікті арттыру және адамның қателігін азайту үшін қолданылады

Сапаны бақылау: Өндіріс процесінде сапаны бақылаудың қатаң шаралары бар Бұған бөлшектердің техникалық сипаттамаларға сәйкес келетіндігін және қорытынды жинақтың мінсіз болуын қамтамасыз ету үшін тексерулер кіреді

Тестілеу және тексеру: Зауыттан шықпас бұрын, әр өрт сөндіру көлігі ауқымды тестілеуден өтеді Бұған жол сынақтары, кабиналық сынақтар және жаңбыр сынақтары кіреді, сондықтан оның нақты жағдайларда күтілетіндей күткендей болуын қамтамасыз етеді

3 Үздіксіз жетілдіру және инновация

Бірде Изузу өрт сөндіру машиналары қызмет етеді, үнемі жетілдіру және инновациялар маңызды:

Кері байланыс ілмегі: Өндірушілер абзац пайдаланушыларынан түсінікті болу үшін кері байланыс жинайды Бұл кері байланыс болашақ дизайнды нақтылау және өнімділікті арттыру үшін қолданылады

Технологиялық жетістіктер: Жаңа технологиялар пайда болғандықтан, олар өрт сөндіру көлігінің мүмкіндіктерін және тиімділігін арттыру үшін жобалық және өндірістік процестерге біріктірілген

Осы қадамдарды орындау арқылы Изузу қауіпсіздік, жұмыс және сенімділіктің ең жоғары стандарттарына сәйкес келетін жоғары сапалы өрт сөндіру машиналарын шығара алады.